Introduction

In the vast world of electronic components, thermistors stand out as crucial elements used for temperature sensing and control. Their name, derived from 'thermal' and 'resistor', indicates their primary function: to vary resistance with changes in temperature. This article explores the principles behind thermistors, their different types, and their extensive applications in various industries.

What is a Thermistor?

A thermistor is a type of resistor whose resistance changes significantly and predictably based on its temperature. Unlike standard resistors, which have a relatively stable resistance, thermistors are highly sensitive to temperature changes. This characteristic makes them invaluable for precision temperature measurement and control.

Types of Thermistors

Thermistors are broadly classified into two categories based on their resistance behavior with temperature changes:

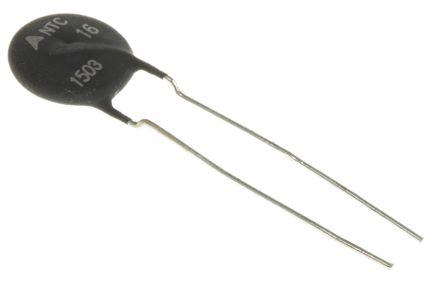

Negative Temperature Coefficient (NTC) Thermistors

NTC thermistors decrease in resistance as the temperature increases. They are made from semiconductor materials such as manganese, nickel, cobalt oxides, and iron. These components are common in applications where rapid response to temperature changes is crucial.

Positive Temperature Coefficient (PTC) Thermistors

In contrast, PTC thermistors increase in resistance as the temperature rises. They are typically made from materials like barium titanate or polycrystalline ceramic. PTC thermistors are often used in applications as circuit protectors and heating elements.

Construction and Design

The construction of thermistors varies but generally involves shaping the thermistor material into a bead, disk, or cylindrical shape, which is then encapsulated with a protective coating to prevent environmental damage. Leads or wires are attached to allow integration into electronic circuits.

Principles of Operation

Thermistors operate based on the principle that the conductivity of semiconductor materials varies with temperature. In NTC thermistors, an increase in temperature provides more energy to the electrons in the semiconductor material, allowing them to move more freely and reducing the material's resistance. Conversely, in PTC thermistors, increased temperature leads to a structure change in the material that reduces electron mobility, thereby increasing resistance.

Applications of Thermistors

Thermistors play a vital role in various applications across many industries due to their sensitivity and quick response to temperature changes.

Consumer Electronics

In consumer electronics, thermistors are used to monitor and control temperatures in devices like smartphones, computers, and refrigerators, ensuring they operate within safe thermal limits.

Automotive Industry

The automotive sector relies on thermistors for controlling and monitoring temperatures in engines and batteries, especially in electric vehicles, to optimize performance and safety.

Medical Devices

Thermistors are integral in medical devices such as incubators and dialysis equipment, where precise temperature control is critical for patient care.

Industrial Systems

In industrial environments, thermistors are used for temperature sensing in processes that require rigorous temperature management to maintain product quality and safety.

Advantages of Using Thermistors

Thermistors offer several advantages over other temperature sensors like thermocouples or Resistance Temperature Detectors (RTDs), including:

- High Sensitivity: Thermistors provide a greater output per degree of temperature change, allowing for more precise temperature control.

- Compact Size: Their small form factor enables integration into various devices without requiring significant space.

- Cost-Effectiveness: Generally, thermistors are less expensive than other types of temperature sensors, making them a popular choice for budget-sensitive applications.

Challenges and Considerations

While thermistors are versatile and useful, they do have limitations, including:

- Non-linearity: The relationship between temperature and resistance in thermistors is non-linear, which can complicate calculations.

- Limited Temperature Range: Thermistors typically have a smaller operational temperature range compared to other sensors, which can limit their use in extreme environments.

Conclusion

Thermistors are indispensable in the modern world, offering efficient and accurate temperature sensing solutions across a wide range of applications. Whether in medical technology, automotive systems, or consumer electronics, thermistors contribute significantly to operational safety, efficacy, and energy efficiency. As technology advances, the development of more sophisticated and durable thermistors will continue to expand their applications and capabilities.

Post a Comment